THE ULTIMATE METALWORKING GUIDE

Discover the world of metalworking with our ultimate guide: from the traditional art of soldering to the cutting-edge technology of laser welding, delve into the many techniques this craft has to offer.

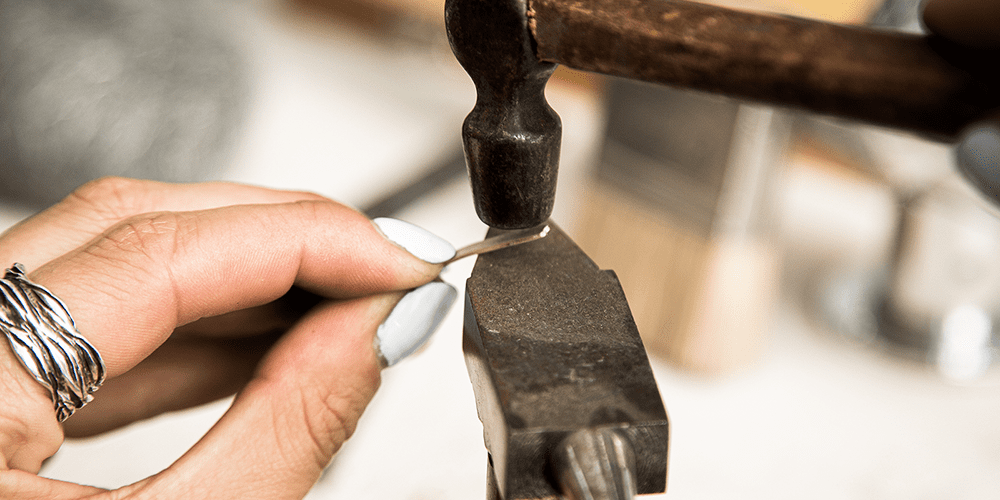

The Art of Metalworking

What Is Metalworking?

The art of metalworking involves shaping and molding metal to produce useful tools, objects, components for equipment, and building structures. The term encompasses a broad and varied range of techniques, abilities, and instruments utilized to create objects in all sizes. In this case, we’ll talk about the processes of metalworking in relation to delicate jewelry pieces.

The Types of Jewelry Metalworking

There are many types of jewelry metalworking techniques that exist. Each technique requires a different set of skills and tools, and the choice of technique will depend on the desired end result. The most common metalworking repairs that our Master Jewelers are involved with include soldering and unsoldering jewelry pieces, laser welding, and stone setting.

Soldering & Unsoldering Jewelry

Jewelry soldering is a metalworking process used to join two or more metal pieces together permanently. It involves heating the metal to its melting point and applying a small amount of filler metal, called solder, to the joint. The solder melts and flows into the joint, forming a strong bond between the metal pieces when it cools and solidifies.

There are several types of solders available for jewelry making, including soft solders, which have a lower melting point, and hard solders, which have a higher melting point. The choice of solder will depend on the type of metal being used, the desired strength of the joint, and the intended use of the piece.

Jewelry soldering requires precise heating and timing to ensure a clean, strong bond. It is an important skill in jewelry making and is used in a variety of applications, including repairing broken jewelry, creating new pieces, and attaching findings, such as clasps and earring hooks, to jewelry components.

To learn more about jewelry soldering, visit our Soldering Repair Services page.

Laser Welding

Laser welding is a type of welding process that uses a high-powered laser to generate the heat needed to join two metal pieces together. The laser beam is focused onto a small area of the metal, which is heated to its melting point. The melted metal then cools and solidifies, forming a strong bond between the two pieces.

Laser welding is a highly precise and efficient method of welding that allows for very fine control over the heat and energy applied to the metal. This makes it possible to achieve extremely fine, precise welds that are not possible with traditional welding methods. It is also ideal for welding metals that are difficult to join using other methods, such as thin sheets of metal or those that are heat-sensitive.

In jewelry making, it is commonly used to repair delicate pieces and to create fine, precise joints. The small size of the laser beam also makes it ideal for welding in tight spaces and for working with small components. However, laser welding requires specialized equipment and training, and it can be more expensive than other welding methods.

The Complications of Jewelry Soldering Repairs

Common Difficulties Found in Chain Repair

Chain repair is typically a simple service, but there are a few cases where it can be more difficult or even impossible. Here are 4 types of issues a chain may exhibit hindering the repair process:

- The chain is hollow

- The chain’s design can’t be fixed

- The metal is strange

- The chain is plated

(Before & After #131)

If your chain happens to involve one of these criteria, we would still like to take a firsthand look to gain a better understanding of the situation and what the potential options are for restoring your chain.

To learn more about chain repairs, visit our Chain Repair Services page.

Common Difficulties Found in Ring Repair

There are actually also quite a few cases in which ring soldering repairs may require extra effort. These cases happen during repairs such as ring resizing. Here are some examples of issues that can affect the ring soldering process:

- Having a ring with stones set in band (accent stones, channel settings, invisible settings, etc.)

- Patterned shanks

- Mixed and alternative metals

(Before & After #125)

If you’re unsure about these scenarios in relation to your ring repair or would just like to learn more about the soldering process when it comes to ring sizing, we can offer you more details about the entire process.

Please feel free to visit our “Ultimate Ring Resizing Guide” to gain some insight!

Have Questions?

“Ring soldering services do require expert knowledge and skilled experience, so we do not recommend trying to fix your ring yourself at home.

When that special ring needs quality care and repair, we are here to provide it. Our process makes it easy to place your order, so you can mail your rings to our certified specialists. We evaluate them for free, and you choose the repairs you want! We then perform the repair and send it right back to you.

Our services include ring resizing (sizing), prong re-tipping, and many other services that put our soldering expertise into practice.”

“Necklace chain soldering services do require expert knowledge and skilled experience, so we do not recommend trying to fix your chain yourself at home.

When that special necklace needs premier repair, our secure process and certified specialists are ready to provide it. We evaluate them for free, and you choose the repairs you want! We then perform the repair and send it right back to you.

Our services include repairing that chain you may have snapped, putting our expertise in soldering into practice.”

“The process of soldering repairs is simple enough, yet requires the experience that our Master Jewelers possess. We aim to leave no trace of our work, which means not only will your repair perfected, but the process itself will be done for you effortlessly.”

Want to look into our Soldering Services?

We are proud members of the

Our team includes gemologists certified by